Multisite certification at Heijmans

In November 2024 I had a chat with Sandra Eilers, Project Leader Quality ...

Read more

With Steven Bremer I had a web interview in May about multisite certification at Tauw. It was an interesting interview because Steven focuses much more on improving his management system of Tauw than on multisite certification. Steven and I have known each other for years through the Qkring, a Dutch network group on QESSH.

Steven is the Quality & Risk Manager at Tauw Netherlands. Tauw Netherlands is part of Tauw Group, an international firm of consulting engineers with branches in the Netherlands, Belgium, Germany, France, Spain and Italy with over 1,200 employees. In the Netherlands the organization operates as Tauw bv, Syntraal and Atrivé bv. Tauw supports clients in a responsible way with clear recommendations taking into account all aspects in the field of the environment, safety, energy, water and the living environment. Tauw Netherlands is organized in the Business Units Industry, Spatial Quality, and Measurement, Inspection & Advise.

He manages the management system of the Dutch part of the Tauw Group. Tauw in the Netherlands has multisite certification with Kiwa for ISO 9001, 14001, CO2 Performance Ladder Level 5, VCA** and for some Dutch process certificates on fieldwork and soil decontamination.

The reason for Tauw to do business with Kiwa is that they can certify the relevant schemes for them. Having multiple schemes at one certifier brings of course a reduction in audit time and costs. The reason for multisite certification is in the first place to have a company certificate for Tauw in the Netherlands. Multisite certification could also bring significant savings on the cost of certification.

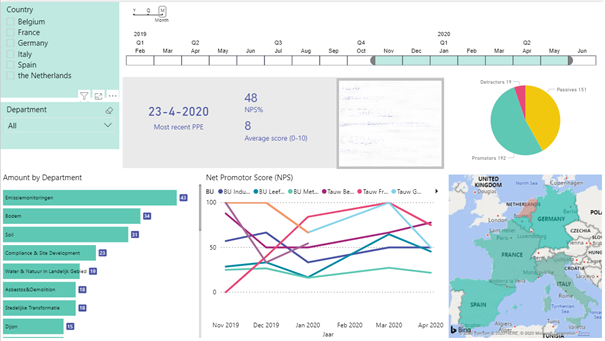

Steven Bremer is in favor of having a single management system for the Netherlands because of maintenance. He manages this integrated management system for about 850 people in the Netherlands. He built this single system for all the sites in SharePoint. The process owners are responsible for the control and reliability of their processes, the documentation needed and the improvements. Steven has built a reporting system with Forms and Power BI. The workflow in some reporting has been automated with Power Automate. For example, when an internal audit has been reported it will be automatically distributed to the relevant people.

He implemented years ago this way of working, documenting the management system top-down, the reporting bottom-up, with consolidation in a cockpit and workflow. For him its nothing special anymore, he is still looking on how to use further digital tools to improve. I think the way he implemented this, is surely a best practice, also considering the rather large number of people he supports with these systems.

According to Steven, Kiwa has professional auditors and they bring added value to Tauw. Sometimes people at Tauw have the feeling that they have to repeat the same story to the same auditor. Normally the external audits should focus in the first year of the 3 years period, the initial or rectification audit, on a global view of the relevant processes. Surveillance audits in the second and third year of the cycles, with less audit time, should focus on processes.

Steven told me that he has regular discussions with the auditors on how to call the sites of Tauw in the Netherlands. In his view there are more locations then real sites, as they are not separate legal entities. For him it’s unclear why this is so relevant to Kiwa. To have sampled audits at these locations has not always added value for Tauw. The business structure is much more relevant than the "physical" structure. Local presence is important for customers and that is why the locations are mentioned on the certificates. Clearly, for Tauw the business units are more important.

Recommendations from Steven to our colleagues - negotiate with your certifiers about audit durations, digitalize your processes as much as possible and orient yourself on risk management. My advice to Steven would be to get a basic understanding of the IAF.MD1.

I agreed with Steven that we will take a look at the calculation of the sites to be sampled, in his view locations.

In November 2024 I had a chat with Sandra Eilers, Project Leader Quality ...

Read more